BBAC celebrates milestone of one million units built

( China Daily )

The one-millionth vehicle rolled of the Beijing Benz Automotive Co Ltd assembly line, symbolizing the Sino-German joint venture's breakthrough to lead the industry with world-class manufacturing quality and operation capacity. The Thursday ceremony in Beijing also celebrated the auto manufacturer's Factory of the Year 2016 title being given to Daimler AG's only joint venture capable of producing the power trains, front-drive and rear-drive models.

Guests and company executives in attendance included Xu Heyi, chairman of BAIC Group, Hubertus Troska, member of the board of management at Daimler AG, responsible for Greater China and Peter Schabert, president and CEO of BBAC.

"The one million units of Mercedes-Benz, formulated with passion and glory, resemble BBAC's speedy development and the countless eforts rooted in China," said Schabert.

This year marks the 11th anniversary of the establishment of the joint venture, whose plant area doubled to more than 4 square kilometers. Industrial value is 16 times that of 2005, and annual productivity increased 46 times.

The one-mi l l ion-uni t achievement was made not only for the 14 localized car models, but also for the three locally-produced engine models.

Chen Hongliang, senior executive vice-president of BBAC, said in a speech that"BBAC undertook drastic changes on its way toward the one-million-unit milestone".

The company has been constantly absorbing the class-leading technologies and state-of-the-art techniques originating from the Mercedes-Benz brand, and has established a future-oriented intelligent manufacturing system.

It has strengthened BBAC's flexible on-demand productivity, elevated the eficiency, and achieved the "best or nothing" Mercedes-Benz quality. BBAC achieved its historic record for selling 143,398 units in the first six months of this year, climbing to second place among its luxury peers in the world's largest market, with a much higher growth rate than the industrial average.

Superior quality

BBAC beat rivals in 13 countries and became the only car manufacturer in China to receive the 2016 Factory of the Year 2016 - Excellent Large Series Assembly awarded by Germany's A. T. Kearney Inc and publication Producktion.

Chen noted, "Backing BBAC's great leap in development, it's our ambition, determination and devotion to erect the benchmarks for the Chinese automotive industry, to promote the upgrade of the sector, and to ofer the same top quality and superior riding experience with the same brand badge."

Based on Daimler AG's"quality feedback loop", BBAC carries out digitalized monitoring and tracking in the production process through a series of world-class intelligent examination and surveillance systems.

All of the core data are synchronized and shared in real time with Daimler to realize globally standardized quality.

The persistence of the company's top quality management resulted in the company receiving the certification of ISO/TS16949:2009 in 2013, the first time a joint venture automobile manufacturer in China has earned the distinction.

One year later, the company's production quality was recognized by Daimler and BBAC started shipping the core engine parts, including crankcases, cylinder heads, and crankshafts to Germany for the group's worldwide used engines.

And now, the plant is also supplying assembled engines to Fujian Benz Automotive Co.

Top talents

Schabert pointed out that,"the achievements nowadays are the results of our thorough and intensive nurturing in talents' education through sophisticated and systematic training mechanisms."

BBAC's quality assurance team includes 10,000 employees, forged by more than 2,600 senior level talents, including four chief technicians, more than 80 senior technicians and more than 400 technicians.

More than 1,200 employees have been sent to Germany since 2008 to participate in the assembly and other functions in Daimler plants.

They came back to China and ignited BBAC's development. Now the joint venture has sent elite teams to help Daimler start new projects in Brazil this year, and in South Africa in 2014.

"We are expecting to bring infinite possibilities for the development of BBAC," Schabert said.

haoyan@chinadaily.com.cn

|

Guests from around the world participate in a ceremony marking 1 million vehicles produced by BBAC.Provided To China Daily |

|

Peter Schabert, president and CEO of BBAC, gives a speech in the ceremony. |

|

The company applies a strict quality control system. |

|

Autonomous processing of equipment-making ensures the consistency of product quality. |

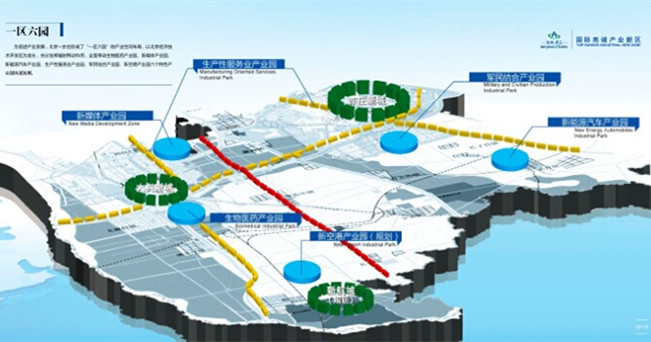

The Area with Six Parks

The Area with Six Parks Global Top 500

Global Top 500